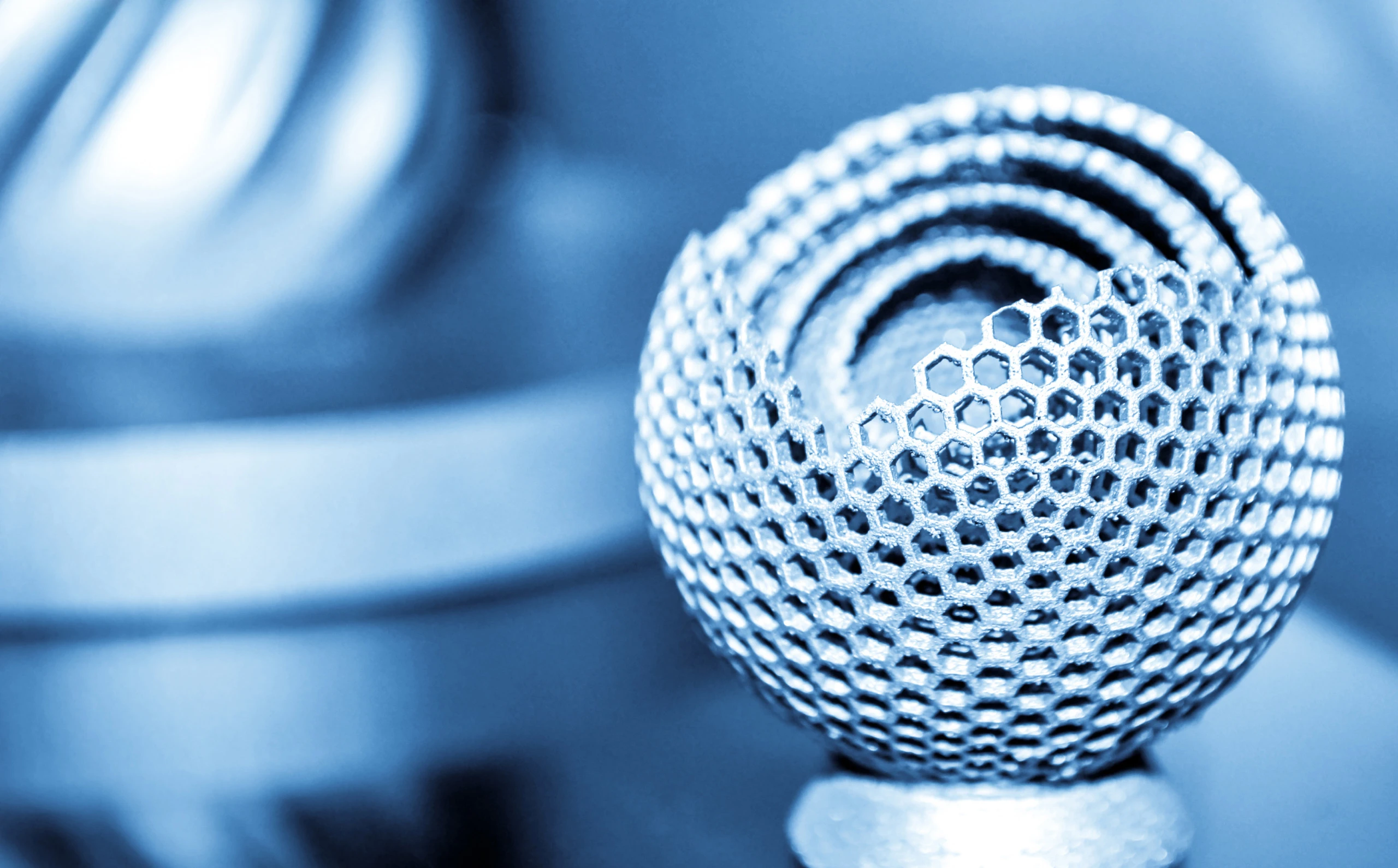

Since the 1990s, 3D printing technology has undergone significant evolution, drawing on techniques such as high-energy thermal fusion and rapid prototyping. In contrast to traditional manufacturing methods, it streamlined iterating steps and increased production efficiency, particularly for intricate components, boasting outstanding manufacturing precision. 3D Parts printed with Titanium alloy exhibit high strength and precise dimensions, outperforming the mechanical capabilities of conventional forging processes. Titanium alloys find extensive applications across biomedical, aerospace, and precision instrument fields owing to their excellent biocompatibility and mechanical capability.

Pros and cons of Titanium Alloy

| Pros | Cons |

| High strength-to-weight ratio | High initial equipment and material costs |

| Complex geometries | Post-processing requirements |

| Customization possibilities | Potential for inconsistencies in quality |

| Reduced material waste | Lower surface quality |

Aluminum is also a common material for 3D metal printing, which one should I choose then?

Aluminum and titanium are both prevalent options for 3D metal printing, each with its own merits and considerations. While both are lightweight materials, their application and production performance differ. Titanium, although about two-thirds heavier than aluminum, achieves specific strength levels with less material due to its inherent strength. Conversely, aluminum stands out for its widespread use and accessibility, being the most common lightweight material. When deciding between the two for a 3D printing project, it’s essential to weigh their differences. The following table outlines their distinctions.

Aluminum vs. Titanium

| Aluminum | Titanium | |

| Density | Lower | Higher |

| Corrosion Resistance | Lower | Higher |

| Conductivity | Excellent electrical and thermal conductivity | Poor electrical conductivity, moderate thermal conductivity |

| Cost | Lower | Higher |

| Strength | Lower | Higher |

| Machinability | Excellent | Moderate |

| Appearance | Reflective | Duller appearance compared to Aluminum |

In summary, aluminum emerges as a cost-effective and widely utilized material, well-suited for parts with less demanding specifications. Conversely, titanium boasts higher strength and cost, making it ideal for intricate and high-performance components.

The Metal 3D Printing Process

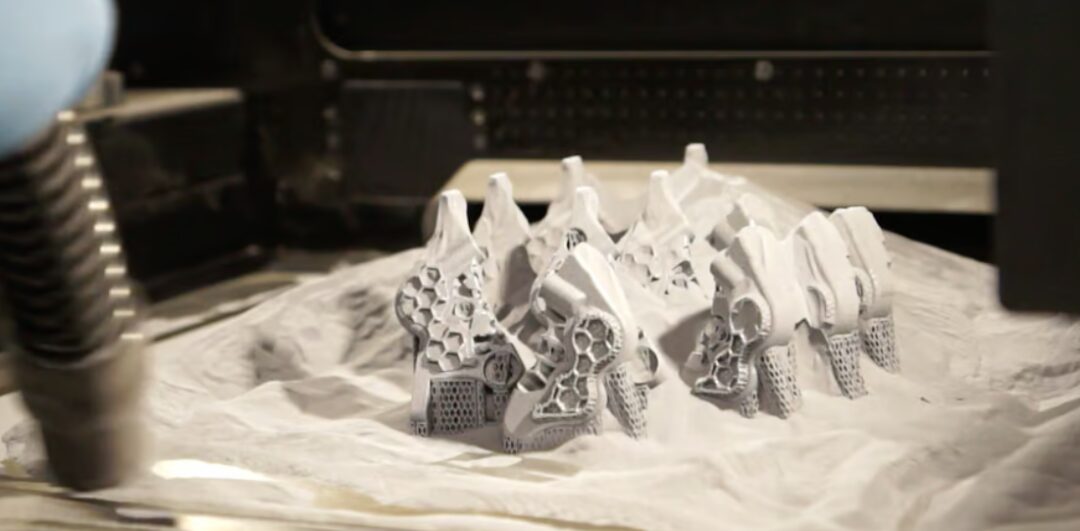

The process of SLM for metal 3D printing with titanium alloy can be broken down into several steps, as outlined below:

- Design and Preparation: CAD Design the 3D model of the part and convert it into the format that the printer reads.

- Powder Bed Preparation: Spread a thin layer of fine titanium alloy powder on the print bed.

- Laser Melting: A high-power laser scans the powder layer by layer according to the CAD model, precisely melting and solidifying it.

- Layer-by-Layer Stacking: After each layer is printed, the print bed descends by one layer and proceeds to the next. This iterative process continues until the product is fully produced.

- Post-Processing: After printing is complete, remove the unmelted powder and perform post-processing, such as removing support structures and surface treatment.

The SLM process can manufacture titanium alloy parts with extremely high density and strength, thus it is widely applied in aerospace, automotive, medical, and other fields.

Titanium Alloy material data sheet

| Category | Indicator | Value | Notes |

| General data | Precision | ±50 micrometers | Forming range:

350x350x420mm |

| Minimum wall thickness | Approximately 0.3-0.4 millimeters | – | |

| Surface Roughness | Ti64_30_030_default.job | Ra 9 – 12 μm, Rz 40 – 80 μm | – |

| Ti64 Performance layer thickness (30 μm) | 9 mm^3/s (32.4 cm^3/h) 1.98 in^3/h | – | |

| Ti64 Speed 1.0 layer thickness(60 μm) | Ra 0.36 – 0.47 x 10^-3 inch | – | |

| Printing rate | Ti64_30_030_default.job | 9 mm^3/s (32.4 cm^3/h) 1.98 in^3/h | – |

| Ti64 Performancelayer thickness (30 μm) | 3.75 mm^3/s (13.5 cm^3/h) | – | |

| Ti64 Speed 1.0 layer thickness(60 μm) | 9 mm^3/s (32.4 cm^3/h) 1.98 in^3/h | – | |

| Physical and chemical properties | Material composition | Titanium, Aluminum, Vanadium, etc. | Aluminum(5.5-6.75%), Vanadium(3.5-4.5%) |

| Relative density | approximately 100% | – | |

| Density | 4.41 g/cm3

1b/in3 |

– | |

| Mechanical properties | Ultimate tensile strength | 1230/1200 ± 50 MPa | – |

| Fraction strain(XY/Z) | 10/11 ± 2/3 % | Minimum after heat treatment 1050/1060 ± 20 MPa | |

| Harness | 320 ± 12 HV5 | Minimum after heat treatment 14/15 ± 1% | |

| Maximum working temperature | Approximately 350℃ / 600°F |

Challenges in Printing Titanium Alloy Ti6Al4V

Titanium alloy Ti6AI4V is widely favored for metal 3D printing due to its outstanding strength and corrosion resistance. However, achieving optimal results with this material presents certain challenges, including the need for advanced equipment, precise atmosphere control, and high-quality powder.

Advanced equipment is essential to ensure that the laser precisely melts the material during the printing process. Moreover, strict atmosphere control is critical to prevent oxidation of the titanium alloy and maintain high printing quality.

Furthermore, the cleanliness and oxygen level of the powder directly impacts the mechanical properties of the final product, so handling and storage requirements for the powder must adhere to specific rigorous standards.

These challenges underscore the meticulous nature of 4D printing with titanium ally, requiring careful attention to detail and adherence to precise processes.

The combination of Titanium Alloy and 3D Printing

Titanium alloy is a highly favored material in additive manufacturing, widely applied in aerospace, medical implants, high-performing sports equipment, and other industries. Ti6Al4V exhibits excellent strength, is lightweight, and boasts outstanding corrosion resistance. The advancement of 3D printing technology has further diversified the applications of titanium alloys, providing customized solutions and more efficient material utilization. This advancement has also shattered the design limitations of traditional manufacturing, leading to revolutionary breakthroughs in the production of complex structures and precision components. Contact us for all your manufacturing needs and bring your project to life with precision and efficiency!