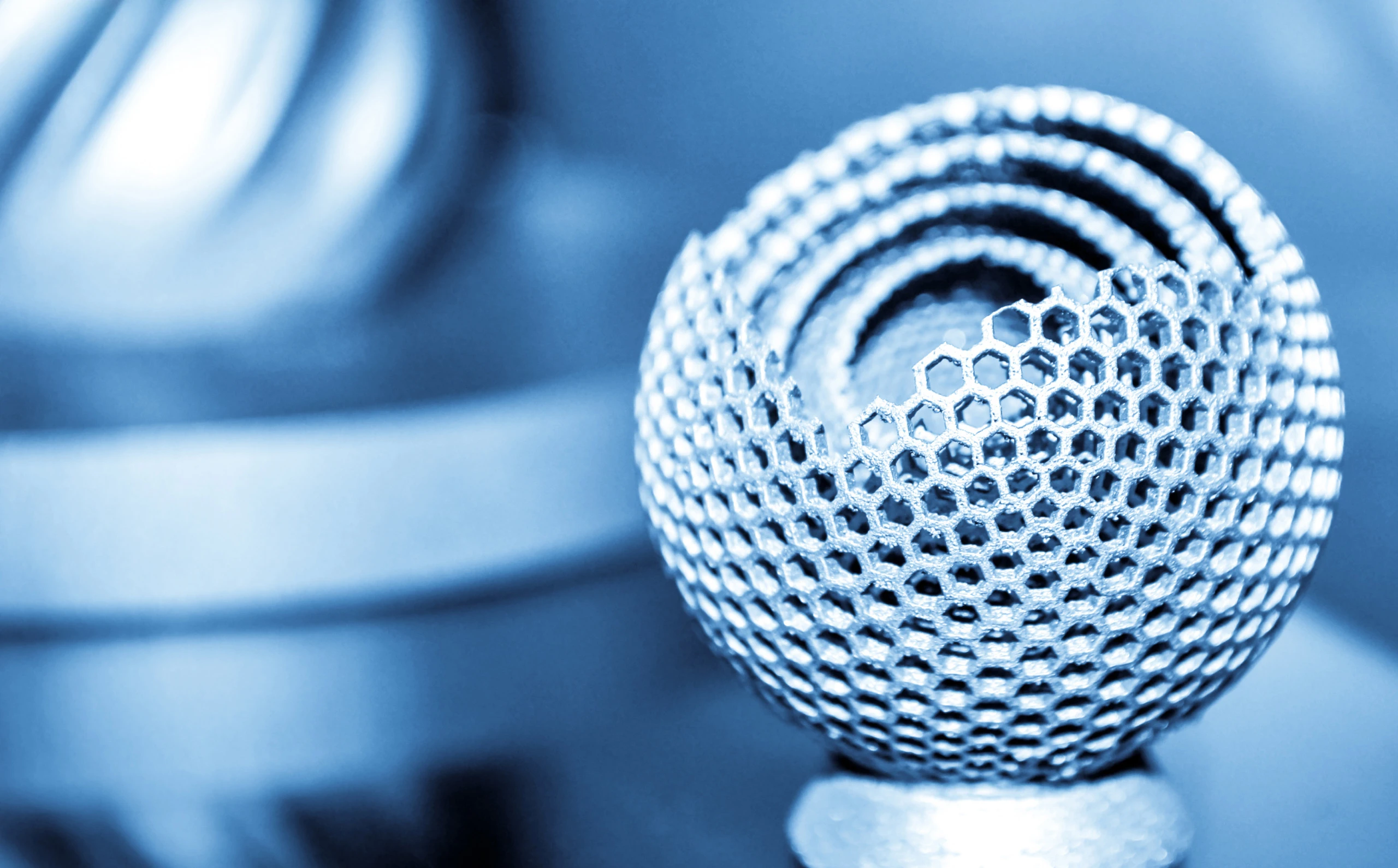

What is Stereolithography (SLA) 3D Printing?

Stereolithography (SLA) 3D printing is an industrial manufacturing method used to produce 3D objects. It utilizes a liquid photopolymer resin that is selectively cured by a UV laser or other light source, layer by layer, to create solid objects. SLA is particularly favored for its ability to produce smooth, injection-molded-like surface finishes, making it suitable for prototyping and certain low-volume production processes. However, it’s essential to note that the choice of light source in SLA printing can significantly impact the accuracy and quality of the finished products.

Common SLA 3D Printing Technologies

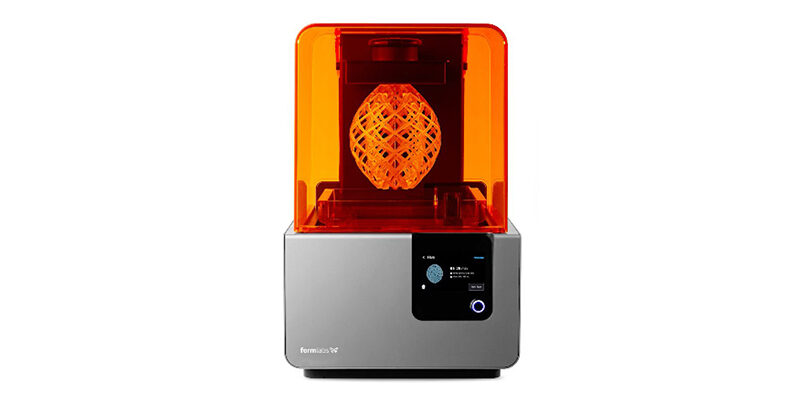

- Desktop Projector Technology (DLP): This technology utilizes LCD projector technology to project each sliced cross-section of the object onto a photosensitive resin layer. Current projectors with resolutions ranging from 2K to 8K are used for this purpose, resulting in the formation of sample components.

- Desktop Low-Power Laser Technology (MICRO-SLA): Low-power infrared lasers are used to scan and solidify layers of liquid resin. The scanning path cannot be adjusted, and the final product is formed by stacking these solidified layers.

- Continuous Liquid Interface Production (CLIP) Technology: CLIP technology produces parts through a balanced photochemical process involving light and oxygen. Light is projected through an oxygen-permeable window into a resin reservoir containing UV-curable resin. As a series of UV images are projected, the part solidifies, and the build platform rises.

- PolyJet Technology: PolyJet SLA 3D printing process involves jetting small droplets of liquid photopolymer through a printing nozzle to form the desired shape. During the process, the soft and hard photopolymer materials are combined.

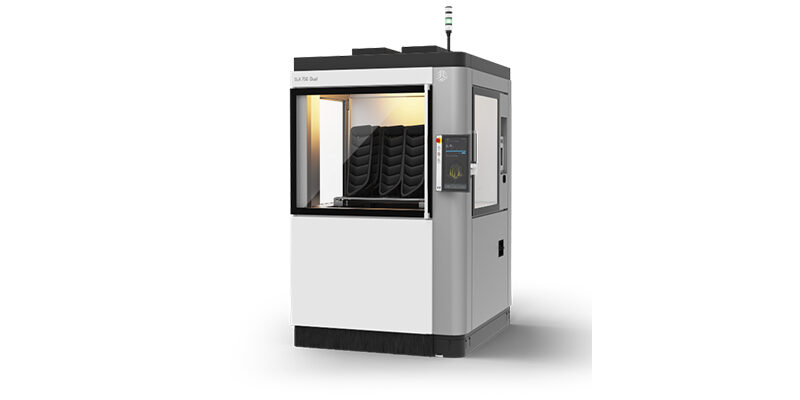

- Laser Sintering Liquid Resin (SLA) Technology: SLA technology utilizes high-power lasers to sinter liquid resin, shaping it via variable spot size and laser path.

Photopolymerization 3D Printing Technology

PolyJet and SLA are two of the most stable processes in photopolymerization 3D printing. The quality of final products in 3D printing is heavily influenced by the chosen printer and production process. Equipment for both PolyJet and SLA typically costs millions and is often floor-standing, akin to CNC machines. As with CNC machines, the stability and precision of the equipment increase with weight, with machines weighing several hundred kilograms.

Both methods can achieve up to a 95% success rate in manufacturing yield. With InstaVoxel’s SLA equipment utilizing laser sintering liquid resin photopolymerization, we can ensure a precision error between 0.01mm and 0.02mm(0.00039-0.00079 inch) for parts produced in a plane ranging from 15 cm to 20cm(5.9-7.87inch).

In conclusion, various photopolymerization 3D printing technologies exist. After reading this article, you now have a better understanding of each process. InstaVoxel is here to provide professional services for all your manufacturing needs. Don’t hesitate to contact us anytime for manufacturing inquiries!